Description

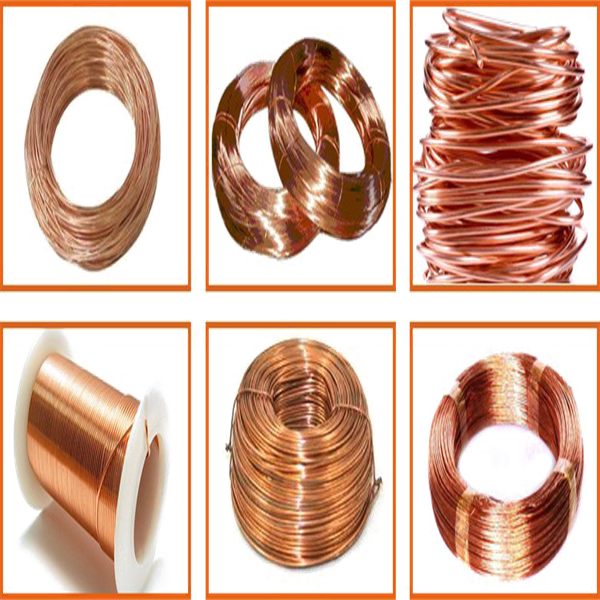

Copper wire specifications:

The shape of the cross-sectional: round or rectangular.

The resistivity of copper wire depends on the type of material and temperature. Each wire has a set of physical and mechanical characteristics.

Different copper wire is determined by the maximum electrical resistance, which operates at a temperature of 20 °C.

Features:

Copper wire with high plasticity, it can be repeatedly bent, but there is a disadvantage: just big soft.

It has a high ductility, strength of the fractures, electrical conductivity and corrosion resistance.

Type:

By appointment copper wire can be divided into: general-purpose wire, for low-temperature thermocouple wire.It is divided into soft and solid wire.

5. Copper Cladding Steel Wire

Feature

1. High intensity: CCS wire has 2 times higher tensile strength than pure copper wire. Pure copper wire is about 215 to 265, then CCS wire can reach 430 to 530.

2. Light weight: lighter 13% than pure copper wire. Under the same wire size and weight, its length is 1.13 times than that of pure copper wire. So buying 1 ton of CCS wire is the same as buying 1.13 tons’ pure copper wire.

3. Saving cost: CCS wire price is just 35% of that of pure copper wire, while its surface quality is the same with pure copper wire.

4. Using of copper cladding steel wire will reduce greatly the production cost while guaranteeing the same quality as pure copper wire.

Property of Copper Cladding Steel Wire:

Good corrosion resistance of copper

High tensile strength of steel

Decreased electrical resistance compared to steel

Much lower impedance at high frequencies than that of steel wire alone

Copper Clad Steel Wire (CCS Wire) finds the following popular applications:

1,Inner conductor of terminal CATV coaxial cable

2,Conductive cord of user communication cable for double conductor telephones.

3,Plug-ins for electronic components.

4,Conductive cord of field wires.

5,Overhead system for power transmission and telephone lines.

6,Overhead-contact systems for railway and Light Rail Transit.

7,Braided shield wire of power cable.

8,Earthing pole for electrical power industry.

Technical Details of Copper Clad Steel Wire:

Material for producing ccs wire: low carbon steel or high carbon steel.

Wire Diameter: 0.20mm –4.88mm

Tensile strength: Low carbon min 350N/mm2; High carbon min 1100N /mm2 or above.

Conductivity : 21% IACS, 30% IACS, 40% IACS or as per client’s requirement.

Packing : in coils or on reels/spools.

Specification: ASTM B910, BS4087 etc.

Application: Wire cable for telephone, telegraph etc.

Packing Spool size:

DIN130mm, DIN160mm, DIN185mm, DIN250mm, DIN400mm, DIN500mm, DIN630mm, DIN800mm

Main Grades

| Classification | United Kingdom (BS) | Germany (DIN) | Japan (JIS) | EN (symbol) | EN (Number) | China | America (ASTM) |

| Copper | C102 | ECu-58 | C1100 | Cu-ETP | CW004A | T2 | C11000 |

| Oxygen-free Copper | C103 | OF-Cu | C1020 | Cu-OF | CW008A | TU1 | C10200 |

| Phosphorized Copper | C106 | SW-Cu | C1201 | Cu-DLP | CW023A | TP1 | C12000 |

| SF-Cu | C12100 | 121 | |||||

| C106 | 2.0090/2.0076 | C12200 | 122 | ||||

| Silver containing Copper | C101 | CuAg0.1 | C1271 | TAg0.08 | C13000 | ||

| C12900 | 129 | ||||||

| Cadmium Copper | C108 | CuCd1 | CuCd1 | CuCd1 | CW131C | TCd1 | C16200 |

| Berryllium Copper | C112 | CuCo2Be | CuCo2Be | CuCo2Be | CW104C | TBe0.6-2.5 | C17600 |

| Brass | CZ125 | CuZn5 | C2100 | CuZn5 | CW500L | H96 | C21000 |

| CZ101 | CuZn10 | 2.023 | CuZn10 | CW501L | CuZn10 | C22000 | 220 |

| CZ102 | CuZn15 | 2.024 | CuZn15 | CW502L | CuZn15 | C23000 | 230 |

| CZ103 | CuZn20 | 2.025 | CuZn20 | CW503L | CuZn20 | C24000 | 240 |

| CZ106 | CuZn30 | 2.0265 | CuZn30 | CW505L | CuZn30 | C26000 | 260 |

| CZ126 | C26100 | ||||||

| CuZn33 | 2.028 | CuZn33 | CuZn33 | C26200 | 262 | ||

| CZ107 | CuZn36 | 2.0335 | CuZn33 | CW506L | C26800 | 268 | |

| CuZn36 | CuZn36 | C27000 | 270 | ||||

| CZ108 | CuZn37 | 2.0321 | CuZn36 | C27400 | 274 | ||

| CuZn37 | CW508L | C27200 | 272 | ||||

| CuZn40 | 2.036 | CuZn40 | CW617N | C28000 | 280 | ||

| CZ109 | CuZn40 | 2.036 | CuZn40 | CW617N | C28000 | 280 | |

| DCB1 | G-CuZn37Al1 | 2.0595.02 | CuZn37Al1-C | CuZn40Y40 | C85800 | 858 | |

| G-CuZn25Al5 | 2.0598.03 | CuZn25Al5Mn4Fe3-C | CuZn19Al6Y20 | C86200 | 862 | ||

| HTB1 | G-CuZn34Al2 | G-CuZn34Al2 | CuZn32Al2Mn2Fe1-C | CuZn30AlFeMn | C86400 | 864 | |

| CZ118 | CuZn36Pb1.5 | 2.0331 | CuZn35Pb1 | CW625N | CuZn35Pb2 | C34000 | 340 |

| Leaded Brass | CZ119 | CuZn36pb1.5 | C3560 | CuZn36pb1.5 | HPb63-3 | C34500 | |

| CZ124 | CuZn36pb3 | CuZn36pb3 | C34700 | 347 | |||

| CuZn37pb0.5 | 2.0332 | CuZn37pb0.5 | C34900 | 349 | |||

| CZ120 | C36000 | 360 | |||||

| CZ123 | CuZn39Pb0.5 | CuZn39Pb0.5 | CuZn37Pb1 | CuZn39Pb0.8 | C36500 | 365 | |

| CuZn32pb2 | CuZn32pb2 | C35300 | 353 | ||||

| CZ129 | CuZn38Pb1.5 | CuZn38Pb1.5 | CuZn38Pb1 | C37000 | 370 | ||

| Z120 | CuZn39Pb2 | 2.038 | CuZn39Pb2 | CuZn39Pb2 | C37700 | 377 | |

| CZ122 | CuZn39pb3 | 2.038 | CuZn39pb3 | CuZn39pb3 | C37800 | 378 | |

| CZ121 | 2.0401 | C38000 | 380 | ||||

| CZ121/3 | CuZn39Pb3 | 2.0401 | CuZn39Pb3 | CuZn39Pb3 | C38500 | 385 | |

| Tin Brass | CuZn38Sn1 | C4640 | CuZn38Sn1As | C46400 | |||

| Phosphor Bronze | PB101 | CuSn4 | C5102 | CuSn4 | CW451K | QSn5-0.2 | C51100 |

| CT1 | G-CuSn10 | 2.1050.01 | CuSn10-C | CuSn8 | C90700 | 907 | |

| PB2 | G-CuSn12 | 2.1052.04 | CuSn12-C | CuSn12-C | C91700 | 917 | |

| PB1 | CuSn10P | CuSn10P | CuSn11P-C | CuSn10P | |||

| Aluminium Bronze | CuAl5As | CuAl5As | C60800 | ||||

| CA104 | CuAl10Ni5Fe4 | 2.0966 | CuAl10Ni5Fe4 | CuAl9Ni5Fe3 | C63000 | 630 | |

| Silicon Resd Brass | G-CuZn15Si4 | SzBC2 | CuZn16Si4-C | C87500 | |||

| SCB3 | G-CuZn33Pb | 2.0290.01 | CuZn33Pb2-C | CuZn33PbY20 | |||

| Leaded Tin Bronze | LB2 | G-CuPb10Sn | LBC3 | CuSn10Pb10-C | C93700 |

Tolerances

Our copper steel wireis manufactured in compliance with the main international specifications.Tighter tolerances are available upon request.Custom tempers are available upon request.

Surface Finishes

Oil-free surface

Electro plating

Hot-dip tin plating

Deburred or rounded edges

Bright and polished surfaces

Coil with protective coatings

Profiled coil by either milling or stamping

Packaging

All of our copper steel wire are packaged as per international standard to prevent any possible damage or loss. By default, we will use thick woven plastic bag to bundle the finished pipes together in batches.

For some special copper steel wire that are vulnerable to dirt, scratches, stress or rough handling, we will suggest wooden case for protection. Kindly note, wooden case can incur extra cost, not only its own cost, but also the increased freight cost, which is especially true for air transportation. For enhanced customer experience, we also provide dedicated package as per your special requirements.

Reviews

There are no reviews yet.